Advertisement feature

Advertisement feature

As part of a cost reduction programme Network Rail has begun to switch to 2-core cables. These cables are cheaper to purchase meaning initial installation costs are reduced. However, as there is no earth core, this requires Class II installation which means that traditional metal enclosures may not be the best solution. This is why many companies are moving to GRP enclosures for their latest products. Spelsberg explain

Conventional single-phase low voltage (LV) installations use 3-core cables to transmit electrical power between the source and the end use equipment. The size of the individual cores is governed by the design current and the total cable length, neither of which will change in the event of a replacement cable being required. The advantage of 3-core cable is that the inclusion of an earth core keeps the application safe without requiring any additional insulation – this can reduce development costs during the R&D stage of a new product design. However, the cable is more expensive which becomes an issue during procurement.

Network Rail has been set a target of reducing overall costs by 20% so it is looking for solutions which can help it achieve this goal. One area targeted for savings is procurement. Because of the regular installation work that is carried out on the rail network, not to mention the regular occurrence of cable theft, Network Rail purchases many hundreds of miles of cabling every year. Network Rail has gone to the lengths of designing a 2-core cable which is cheaper that traditional 3-core – this must now be specified for all trackside installations.

Network Rail has been set a target of reducing overall costs by 20% so it is looking for solutions which can help it achieve this goal. One area targeted for savings is procurement. Because of the regular installation work that is carried out on the rail network, not to mention the regular occurrence of cable theft, Network Rail purchases many hundreds of miles of cabling every year. Network Rail has gone to the lengths of designing a 2-core cable which is cheaper that traditional 3-core – this must now be specified for all trackside installations.

Protection is key

However, in order to install the cheaper cable, while still adhering to electrical installation regulations, it is necessary that the application is built to meet Class II protection or double insulation standards. This means that no single failure can result in dangerous voltage becoming exposed and causing an electric shock.

While 2-core cabling has the potential to save a great deal in replacement costs, many current trackside products may be unsuitable for this solution as the metal enclosures used to house the electronics are often unable to provide the insulation required. This has led many OEMs to move away from traditional enclosure products in favour of glass reinforced polyester (GRP) alternatives. Sourced from the right supplier these enclosures not only provide better insulation, but they are cheaper and easier to install as well, all of which helps Network Rail in achieving their target savings.

MGB Engineering, a manufacturer of safety critical rail products, has recently launched a new FSP switchgear enclosure, a component of the Functional Supply Point (FSP), which takes advantage of GRP enclosures to provide Class II insulation. Mike James, engineering director, explained how they worked with their supplier, Spelsberg UK, to design an efficient and reliable solution, “We had previously worked with Spelsberg on another project so we were aware of the company’s technical knowledge and design capabilities. So when we began to think about the new FSP switchgear we approached Spelsberg to see what ideas it could bring to the table. It turned out that it had a product on the shelf which could be developed to produce a Class II power feed, and so we set out a new project to deliver a solution which would be competitive in terms of procurement and installation costs, while having the additional benefit of reduced replacement costs in the event of cable theft.”

MGB Engineering, a manufacturer of safety critical rail products, has recently launched a new FSP switchgear enclosure, a component of the Functional Supply Point (FSP), which takes advantage of GRP enclosures to provide Class II insulation. Mike James, engineering director, explained how they worked with their supplier, Spelsberg UK, to design an efficient and reliable solution, “We had previously worked with Spelsberg on another project so we were aware of the company’s technical knowledge and design capabilities. So when we began to think about the new FSP switchgear we approached Spelsberg to see what ideas it could bring to the table. It turned out that it had a product on the shelf which could be developed to produce a Class II power feed, and so we set out a new project to deliver a solution which would be competitive in terms of procurement and installation costs, while having the additional benefit of reduced replacement costs in the event of cable theft.”

The purpose of the enclosure is to be connected to a radial circuit and provide circuit protection and isolation points for a number of functional circuits as well as surge suppression, if required. The enclosure had to be IP4X rated and contain terminals for the radial supply, in and out, capable of accepting 120mm2 conductors.

The key design criteria for the new FSP switchgear was that it had to fit the legacy size of 400mm x 400mm in order to allow an easy swap with the incumbent product and keep installation costs to a minimum. In addition the entire solution had to be designed specifically to work with the Network Rail designed Class II cable.

From this point Spelsberg worked closely with MGB Engineering on specifying the correct enclosure and developing the design – which had to account for Class II cable termination and glanding while also conforming to IEC (International Electrotechnical Commission) and rail industry standards. Over the course of a year, prototypes were developed and innovative solutions incorporated into the final design, which was granted the Network Rail Certificate of Acceptance in May 2013.

Challenges

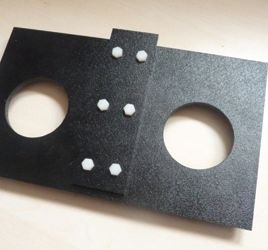

One of the major challenges in the project was the installation of large cables into the enclosure. Even with the introduction of removable gland plates this is no easy task, having to work in a confined area with large, inflexible cables. MGB Engineering and Spelsberg were able to collaborate on this point and developed the MAGplate. The polycarbonate MAGplate allows the power cables to be made off at a convenient point in front of the FSP enclosure and then the gland plate assembly simply pushes into position – no additional fixing is required.

This design makes site installation much quicker, saving time and money. The design of the MAGplate means maintenance is simplified and an individual power cable can be changed without disturbing the other. Extensive testing has resulted in an extremely strong assembly and a practical solution to an age old problem of installing power cables of up to 120mm2 in either copper or aluminium.

The finished design also had to incorporate test points for the supply cables to enable maintenance engineers to test for a live circuit before opening the enclosure as well as individual isolators for each circuit with the facility to be locked off. The fuse protection can be accessed by only removing a clear cover and so does not require the enclosure to be opened, thereby reducing the danger to engineers.

Darren Field, area sales manager at Spelsberg concluded, “This product has passed through some very rigorous testing procedures in order to achieve final acceptance and finally the hard work has paid off.”

Spelsberg

T: 01952 605 849