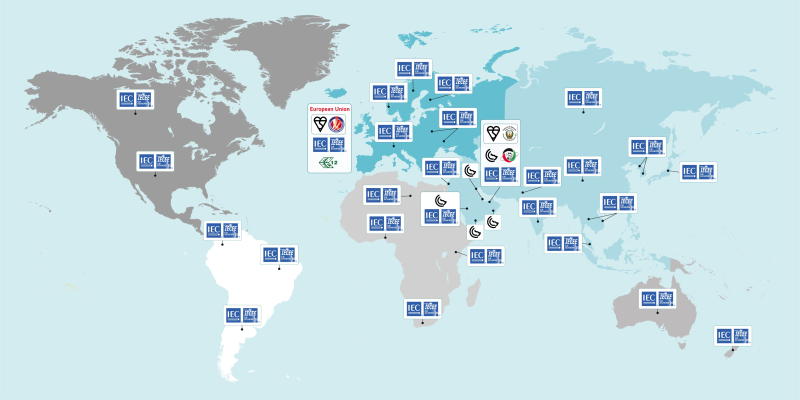

The IECEE CB scheme, also known as the CB scheme, is a scheme based on product-testing standards for electrotechnical equipment (EE) agreed by all 60 members of the International Electrotechnical Committee (IEC). The IEC is a non-profit organization that develops and publishes standards concerning electrical technologies that reach over 150 countries.

The IECEE CB scheme, also known as the CB scheme, is a scheme based on product-testing standards for electrotechnical equipment (EE) agreed by all 60 members of the International Electrotechnical Committee (IEC). The IEC is a non-profit organization that develops and publishes standards concerning electrical technologies that reach over 150 countries.

The CB scheme

The CB scheme was developed to harmonise standards and reduce complexity and supply-chain risks on an international level. The scheme involves testing products to internationally-agreed standards, using internationally, consistent procedures.

The programme is rigorous, and systematically monitored by NCBs (the national certification bodies authorised to carry out the tests and certify products) audit and peer assess each other to make sure they’re working in the same way and to the same criteria.

CB certification

Once a CB certificate has been achieved, local certification is a potential next stage. Even in countries where members of the scheme have signed the IECEE agreement — for example, Australia, Germany and South Africa — there can be additional requirements.

Therefore, where exporting is concerned, a CB certificate can be an important ‘first staging post’ on the route to compliance.

Why choose CB certification?

CB certificates:

• Lower the barriers to market entry, even in countries where members haven’t signed the IEC agreement

• Demonstrate products meet internationally agreed standards — and that they’ve passed the first step towards local-market compliance

Achieving certification with BSI

BSI can both help an organization to achieve CB certification and access to a chosen export market by providing support with achieving compliance to the relevant local standards. BSI also provides the opportunity to upgrade a CB certificate to the Kitemark.

The products BSI tests and certifies

As a fully participating member of the CB scheme and an NCB, BSI tests and certifies a range of electrotechnical products in the following categories:

• Electronic controls

• EMC (electromagnetic compatibility) of products

• Household equipment

• Lighting — including luminaires

• Measurement, control and laboratory equipment

• Medical electrical equipment

• IT and Office equipment

• Audio video information and communication technology

The BSI Kitemark

Additionally, BSI can use CB certification as the base for not only market-specific certification, but also for the BSI Kitemark. Recognised in many markets and exclusive to BSI, the Kitemark can make a big difference to exporters, and BSI can help products stand out in international markets by certifying products to the Kitemark.

Flexible service

BSI can tailor services to the size of a business and offers the following options, which can be achieved in a variety of different levels depending on the individual needs of a business.

Testing products can be done at BSI’s own laboratory in Loughborough – here BSI will test products and issue a CB certificate at the end of the process.

The scheme also allows organizations to test products at their own facilities and receive certificates from the NCB like BSI. The scheme follows a 4 stages process to ensure the quality of results is correct, repeatable and quality maintained. This allows manufacturers to benefit from the investment in facilities they have made.

Stage 1 is the Testing at Manufacturers Premises (TMP) where the testing is carried out wholly by the CBTL (CB Testing Laboratory) attached to the NCB (Notified Certification Body) at the manufacturers site. In such case BSI sends a member of the testing team to conduct the test at the client’s site.

Stage 2 is the Witness Manufacturing Testing (WMT) where testing is carried out by the manufacturer and is partially witnessed by ta CBTL at the NCB at the manufacturer site. At this stage BSI witnesses a certain number of projects and issue WMT status on successful completion.

Stage 3 is called Supervised Manufacturers Testing (SMT) where testing us carried out by the manufacturer and is partially witnessed by a CBTL or the NCB at the manufacturer site. At this point the manufacturer would submit their testing plans to the CBTL / NCB for approval.

Stage 4 is the Recognised Manufacturer Testing (RMT) where testing is carried out by the manufacturer and selected submissions are partially witnessed by a CBTL or the NCB at the manufacturer site.

All stages require initial and annual inspections / assessment of suitability of facilities.

Gap analysis

For businesses thinking of witness or supervised testing, BSI can carry out a gap analysis to help identify any required investments — in equipment and processes. In turn, businesses will be able to carry out their own cost/benefit analysis.

For further information visit the BSI website.