Surge Protection Devices look at the main factors that panel builders need to take into account to ensure protection against surges and lightning strikes

Surge Protection Devices look at the main factors that panel builders need to take into account to ensure protection against surges and lightning strikes

Surge protection for electrical installations and electronic components has gained momentum and recognition in both international, European and most recently British standards, and from 1st January 2012 is included in the 1st Amendment of the Wiring Regulations BS7671.

Over the last 20 years electronic components have become smaller, faster, and therefore, more vulnerable to overvoltages including direct or nearby lightning strikes and surges. These modern smaller, faster electronic components are damaged on a daily basis causing lost production, computer down-time and heavy consequential losses.

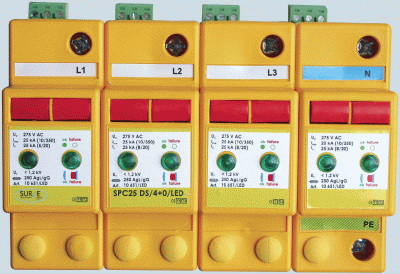

Nearly every modern appliance, machine etc has vulnerable components which need protection – a fact recognised by the inclusion of surge protection in the Wiring Regulations for the first time. There are three types of arrester used for power protection, and it is important that the correct arrester is chosen and is installed with consideration being taken of the manufacturers recommendations as to cable size/length and back-up MCB or fuse size.

The three types of surge protection devices for power systems are:

Type 1: Often referred to as a lightning current arrester or equipotential bonding SPD – fitted at the main incoming switchboard position. To comply to the regulations it must be fitted where the building has external lightning protection e.g. lightning conductors or is at risk of a direct strike or where the building is fed via an overhead line.

Type 2: Referred to as heavy duty overvoltage or surge protection devices. They are fitted at the main incomer where there is no risk of lightning strike, no external lightning protection and cables feeding buildings are underground. T2 surge protection devices should also be fitted at sub-distribution boards feeding electronic equipment more than ten metres away from the main incomer.

Type 3: Referred to as light duty overvoltage or surge protection devices. These are fitted at or very close to the final equipment to be protected e.g. socket outlets or fire/burglar alarm panels.

Origins of surges

Origins of surges

Approximately 20% of surges come from external sources to the building. Therefore, by fitting a combined T1 + T2 arrester at the incoming mains position, you cover lightning impulses and the 20% of surges coming from outside your building. This is the route most switchboard/panel builders have chosen to follow. However, it’s still possible for the panel builder to make a costly selection error, as T1 SPDs have four levels. These are determined by carrying out a risk assessment – generally the panel manufacturer should be given this information by the consultant.

The four levels of lightning strike intensity are:

Type 1 – Level I: Type 1 SPDs must withstand 100kA 10/350µs.

Type 1 – Level II: Type 1 SPDs must withstand 75kA 10/350µs.

Type 1 – Level III: Type 1 SPDs must withstand 50kA 10/350µs.

Type 1 – Level IIII: Type 1 SPDs must withstand 50kA 10/350µs.

This means that for a Level IV installation which is 3-phase and neutral e.g. 4-poles 50kA minimum is divided by 4 = 12.5kA 10/350µs per pole is the absolute minimum requirement for a T1 arrester. Similarly if the installation is single-phase and neutral 50kA is divided by the 2-poles = 25kA 10/350µs is the absolute minimum requirement.

As for Level 1 installations a 3-phase and neutral installation e.g. 4-poles, each pole has to be 25kA 10/350µs minimum, for a 2-pole SP&N installation each pole has to be 50kA 10/350µs minimum. Get this wrong and costly visits to site to upgrade the arrester are possible.

Most arresters are very easy to fit and are wired in parallel. This means for a retro-fit installation, no changes to the existing fixed wiring is necessary – just a simple connection to the phases, neutral and earth connections.

As mentioned earlier, manufacturers installation notes must be followed as some manufacturers have different recommendations as to back-up fuse size and cable size and length. This difference is due to the type of technology employed by the manufacturer and differs significantly e.g. some manufacturers recommend a minimum back-up fuse of 160A for example, for others like Surge Protection Devices, 63A is the difference in space requirement and cost is significant.