Mitsubishi HiTec Paper is one of the most prominent speciality paper manufacturers worldwide. Headquartered in Germany, Mitsubishi has been making paper at its Bielefeld mill since 1799. With over 500 employees, two paper machines and five coating machines, they manufacture approximately 150,000 tons of speciality paper every year.

Mitsubishi HiTec Paper is one of the most prominent speciality paper manufacturers worldwide. Headquartered in Germany, Mitsubishi has been making paper at its Bielefeld mill since 1799. With over 500 employees, two paper machines and five coating machines, they manufacture approximately 150,000 tons of speciality paper every year.

Their product portfolio encompasses inkjet paper, thermal paper, carbonless paper, label paper and barrier paper for flexible and protective packaging. Since the factory produces a large amount of paper, any system failure would result in significant economic loss for the company. As a result, the production equipment at the factory has been designed with an ungrounded power supply and a Bender insulation monitoring device (IMD).

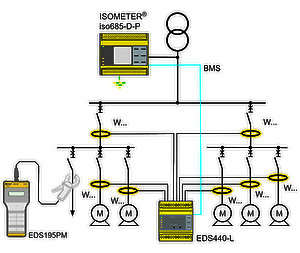

Typical illustration of insulation monitoring combined with a fault location system.

Advantage of ungrounded systems

The advantage of using an ungrounded system is that there is no connection between power source (transformer) and earth. This means electrical installations still function in the event of a ground fault occurring. In a classic grounded system, the fault would trip a protective device, shutting off the power supply and halting production. Insulation faults such as this can often be traced back to wet conditions, moisture or mechanical/electrical loads, all of which are high risk factors in a paper factory which uses a lot of water in its processes.

In the Mitsubishi HiTec Paper plant, these potentially destructive problems are prevented with a Bender insulation monitoring device – iso685-D-P combined with fault location technology – EDS3090. The iso685-D-P identifies and reports insulation faults before they are critical in advance of a failure occurring.

The EDS3090 is paired with the iso685-D-P to quickly and automatically pinpoint the exact location of the fault. Maintenance teams are then notified of faults in advance by a pre-alarm feature. This prevents critical production interruptions, which are disastrous for paper production due of the length of time it takes to get the machines back up and running.

Mitsubishi HiTec Paper maintenance technicians received training in Bender’s Grünberg headquarters to ensure they were comfortable with the monitoring device and portable fault location kit. As a result, they can now locate faults in house, eliminating the need for a Bender technician to attend site and resolve the issue.

Mitsubishi HiTec Paper maintenance technicians received training in Bender’s Grünberg headquarters to ensure they were comfortable with the monitoring device and portable fault location kit. As a result, they can now locate faults in house, eliminating the need for a Bender technician to attend site and resolve the issue.

The insulation values and continuous data recordings are displayed in a control room to keep employees informed about the status of the production equipment at all times.

The application of an insulation monitoring device with fault location technology has enabled quicker, safer identification of insulation faults. This has improved equipment availability, reduced maintenance costs, and ensures high availability of production.

For more information contact Bender UK on: industrialsales@bender-uk.com or +44 (0) 1229 480123, or visit www.bender-uk.com.