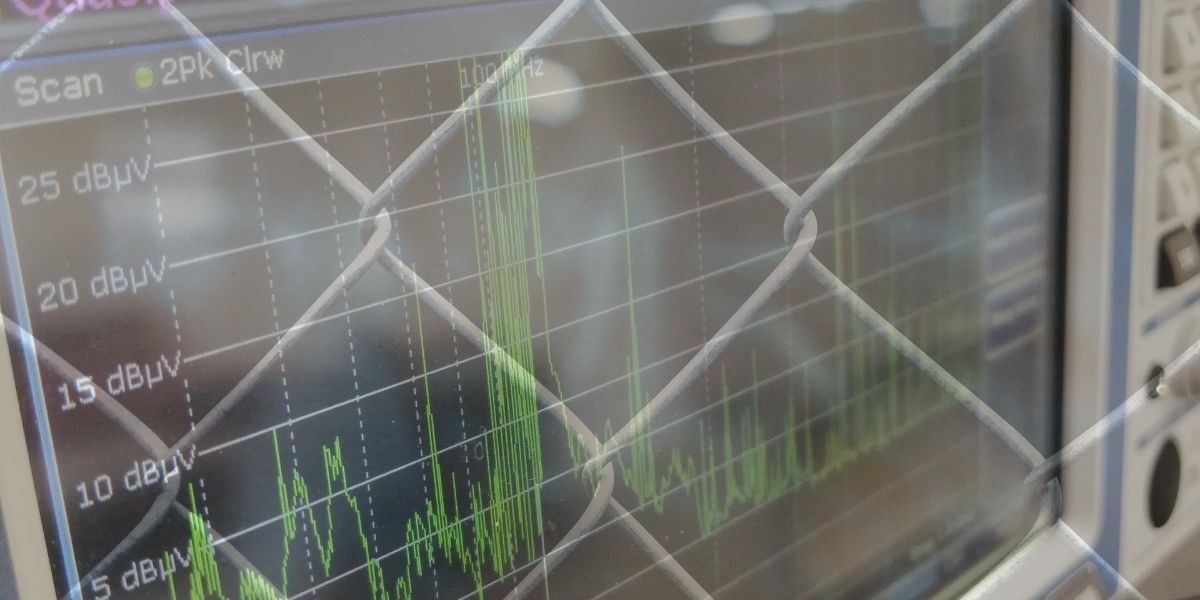

In today’s interconnected world, industries such as medical, safety engineering, and defence operate under stringent regulations, particularly when it comes to safeguarding against electromagnetic interference (EMI). The reliability of electronic devices at Tempest levels and the assurance of security are paramount concerns, with EMI shielding playing a pivotal role in achieving these objectives.

Crucial EMI Shielding: Fortifying Reliability and Security

Electromagnetic interference (EMI), possesses the potential to disrupt electronics and compromise sensitive data. In industries where both lives and missions are at stake, such as medical, safety, defence, and aerospace, EMI stands as a critical concern. EMI shielding is the bedrock, serving as an essential protective barrier like a faraday cage that not only prevents unwanted electromagnetic emissions from escaping devices but also shields them from external interference.

Transparent EMI Glass with ITO Technology: Setting the Standard

At Display Technology, we harness innovative solutions like transparent EMI glass, enhanced with Indium Tin Oxide (ITO) technology, to ensure EMI compliance. This specialised glass maintains the transparency of displays while offering exceptional EMI shielding capabilities:

Transparency: Vital for displays, ensuring that visuals remain uncompromised in applications where clarity is absolutely vital.

ITO Technology: Expertly applied to the glass surface, it expertly disperses electromagnetic interference while preserving display visibility.

Copper Mesh for Resilient Displays: Strengthening the Fortress

To further fortify EMI shielding in our TFT display assemblies, we employ copper mesh boasting a minimum transmission rate of 90%. Copper’s remarkable conductivity serves as a stalwart defence against electromagnetic interference, ensuring that our displays maintain peak performance even in the face of challenging conditions.

Silver-Coated Frame for Grounding: Completing the Shielding Circuit

In the final step of the EMI shielding circuit within our defence TFT displays, a silver-coated frame envelops the EMI glass. This frame serves as a grounding mechanism through the TFT display bezel, efficiently dissipating unwanted electromagnetic energy, neutralising interference, and effectively creating a Faraday cage.

Optical Bonding: Elevating Performance and Readability

But our commitment to creating superior TFT display assemblies doesn’t end with EMI shielding. We also leverage advanced optical bonding techniques. Optical bonding involves bonding a cover glass or touch screen directly to an LCD cell, eliminating air gaps and enhancing visibility by reducing reflections and minimising glare. At Display Technology, we use our VacuBond® process, which inserts a high-quality Opto Gel between the cover glass/touch screen and LCD in a controlled clean room environment. This process significantly reduces light reflection on the surfaces by up to 99 percent, resulting in outstanding readability, perfect contrast, and colour brilliance, even in challenging outdoor and bright light conditions.

Our Commitment: Unwavering Dependability

At Display Technology, our dedication lies in ensuring that electronic devices consistently perform with unwavering dependability, safeguarding sensitive industries and critical missions alike. If you have any questions or wish to discuss how our technology can benefit your specific needs, please do not hesitate to reach out to our team. Your success is our mission.

Click here to find out more

Editorial Contact:

Emma Claridge, Display Technology Ltd

Tel: +44 (0) 1480 411600

Email: emma@displaytechnology.co.uk

Contact Details for Publication:

Tel: +44 (0) 1480 411600

Web: www.displaytechnology.co.uk

Email: info@displaytechnology.co.uk