For over 25 years legacy computer aided design (CAD) systems have been helping businesses become more productive. However, as Ken Christie, director of EPLAN UK explains, companies that rely on legacy systems risk falling behind those who utilise newer, more innovative tools.

For over 25 years legacy computer aided design (CAD) systems have been helping businesses become more productive. However, as Ken Christie, director of EPLAN UK explains, companies that rely on legacy systems risk falling behind those who utilise newer, more innovative tools.

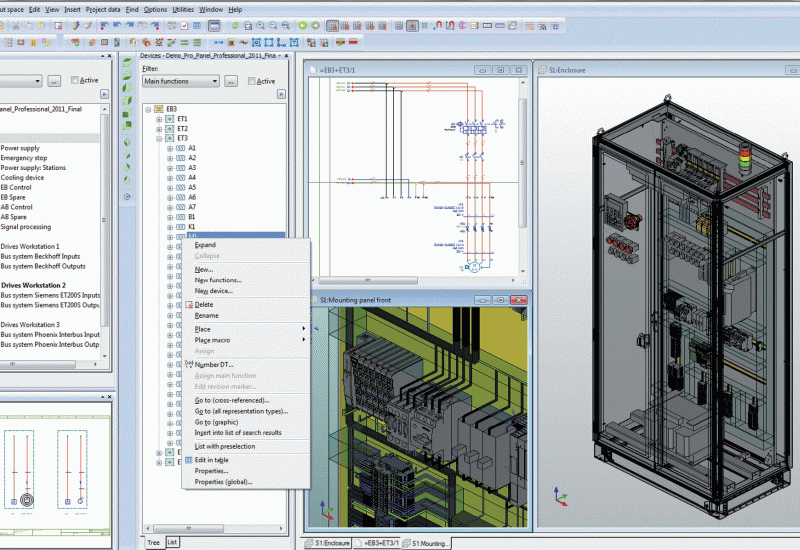

Most electrical design in the UK is still performed using simple, two dimensional CAD systems that produce flat drawings, where all accompanying lists and documents have to be researched and assembled separately. However, users are increasingly turning to newer, more innovative design tools that not only allow these functions to be performed automatically and instantaneously, but that have also been proven to deliver cost savings while improving design integrity and project turnaround times.

For example, EPLAN software contains all the design tools and report generators required. This helps to ensure greater speed, accuracy and flexibility in product development and order fulfilment.

The EPLAN software also includes automatic error checking features, which make it virtually impossible for errors to slip into project build packages, and which largely eliminate the time consuming error checks necessary with legacy systems.

For end users that purchase equipment from various suppliers, EPLAN offers reference tools that compare and contrast incoming designs to make sure they adhere to established quality and technical standards. This ensures that new project planning does not set out on the wrong track and that errors are detected early on, before having potentially detrimental cost consequences in manufacturing and operation.

A key feature of EPLAN software is that it is database driven. There is a myriad of device data and components that can be accessed via EPLAN’s database and it includes macros of sub-circuits, assembly drawings, function templates for intelligent device selection, international designations, preview images and entire manuals.

EPLAN includes around 200,000 pieces of manufacturer created component and device data, which enables users to easily select and apply the data or components required during a project, reducing project drafting and documentation by between 50-80%.

Saving time

Saving time

The ability to automate the creation of recurrent content effectively negates the need for the time consuming creation of master data and provides integrated data for intelligent design, precisely fitting assemblies, virtual wiring and sustainably shortened product development and production cycles.

The EPLAN database can convert project documentation in minutes to the language that customers, vendors and subcontractors require, and export it in one of many common file formats.

The EPLAN database can also be linked via a company’s PLM, PDM, ERP or other enterprise systems to sales, purchasing, accounting, manufacturing, service and other departments. This acts like a digital highway – linking engineering disciplines not only with one another, but also with other vital business disciplines, as well as customers and suppliers.

In addition, EPLAN’s software (which is available in 16 languages with more available thanks to its Unicode capability), fosters collaborative workflows, interdepartmental and global integration, the standardisation and reuse of content, data reliability and consistency, and mechatronic design. Projects can also be structured from the outset to allow for automatic conversion from the IEC or European DIN to the North American NFPA industry standards.

Value

For users of electrical design software such as EPLAN, the real value lies in its capability and flexibility. EPLAN also has a wide partnership network, which provides users with a central web-based database that can hold a large archive of up to date information ready for insertion into a project.

Modern electrical design software can act as a key catalyst in changing how design workflows are structured and to standardise product content to fully exploit the capability of the common platform to store and reuse data.

EPLAN

T: 01709 704 100