Main features

Main features

• Sweep frequency range: 0.1 Hz – 25 MHz (selectable)

• Dynamic range: >150 dB

• Computer interface: USB and Bluetooth

• Battery backup (optional): for 4 hours of operation

• Typical sweep time less than 20 seconds (20 Hz – 2 MHz)

• Superior frequency response in noisy environment

• Sample points per sweep: 1 046 points by default, 32 000 points total

• Correlation calculation per the C57.149-2012 and DL/T 911-2004 standards

• Enabled test result comparison due to possibility of importing data from other manufacturers

• PC based analysis software with user friendly interface with pre-defined test plans and reporting feature for greater efficiency and productivity

• 3-years warranty included with the product. 1-year extension option available upon the registration

Applications

• Potential mechanical and electrical problems detection in power transformers

• Quick test where the fingerprint is compared to a post event response

• Movement of the active parts detection (caused by transportation, earthquakes), or mechanical impacts due to short-circuit forces after a failure

Test Results Interpretation Feature

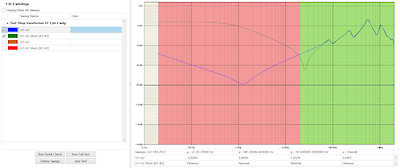

DV-FRA software provides an analytical tool that can perform correlation between two traces per the IEEE C57.149-2012, or DL/T 911-2004 standard.

Features and Benefits

Sweep Frequency Range and Sweep Time

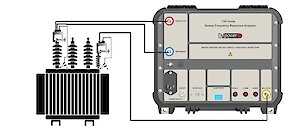

The FRA500’s sweep range is user-selectable from 0.1 Hz – 25 MHz. A typical test sweep time, with frequency ranging from 20 Hz to 2 MHz is less than 20 seconds. A quick sweep test can be performed in under 10 seconds to confirm proper cable connections.

Output Voltages

The FRA500’s test voltage range is programmable from 0.2 Vpp to 20 Vpp in 0.2 Vpp steps. This enables the user to match the test voltage to tests performed by another manufacturer’s device.

Dynamic Ranges

The FRA500 offers a dynamic range greater than 150 dB with a measurement accuracy of ±0.1 dB from +10 to -40 dB and ±0.5 down to -100 dB.

The higher dynamic range eliminates the effects of noise and facilitates the comparison of different sweeps.

Computer Interfaces

The FRA500 is computer-controlled via USB or wirelessly via Bluetooth. The Bluetooth feature allows test personnel to be at a comfortable distance from the transformer for increased safety and productivity.

Optional Battery Backup

An optional built-in battery backup is also available that can provide power for up to four hours. The FRA500 uses a sealed lead acid battery (12V, 7AH).

Self-check test

As included accessories, there is always verification box intended for the self-check of the unit.

FRA500 can confirm the mechanical integrity of the transformer by comparing the frequency response of the transformer with the previously known results. Every transformer has a unique frequency response system which changes if the mechanical geometry of the transformer is changed. These changes can occur due to physical movement or transportation. The physical geometry can also change if the transformer experiences high fault current due to internal or external fault. The fingerprint comparison of the frequency response system can be used to detect power transformer problems such as:

• Core movements

• Shorted turns or open windings

• Winding displacements or deformations

• Winding connection problems

• Broken clamping structures

• Faulty core grounds

• Core connection problems

FRA500 injects a sine wave signal with constant amplitude and variable frequency to one side of a transformer winding. The amplitude and phase angle values of the reference (output) signal are then compared with the corresponding values of the measured signal (from the second side of the winding). The ratio of the measured signal and reference signal magnitude is graphically displayed in dB through the full sweep frequency. The phase difference value between the measured and reference signals are also displayed through the full sweep frequency.

FRA500 injects a sine wave signal with constant amplitude and variable frequency to one side of a transformer winding. The amplitude and phase angle values of the reference (output) signal are then compared with the corresponding values of the measured signal (from the second side of the winding). The ratio of the measured signal and reference signal magnitude is graphically displayed in dB through the full sweep frequency. The phase difference value between the measured and reference signals are also displayed through the full sweep frequency.