Hima-Sella has commenced work on a site wide PLC upgrade programme for a major UK refinery.

Hima-Sella has commenced work on a site wide PLC upgrade programme for a major UK refinery.

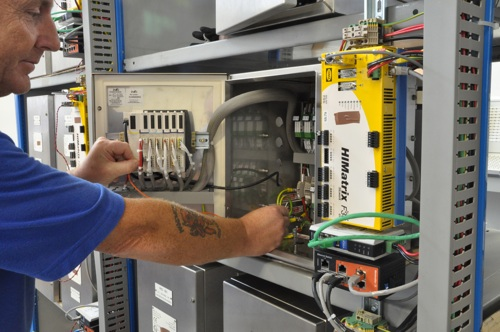

This follows the customer’s formal acceptance of Hima-Sella’s Remote I/O and Network box designs, to be used for the programme.

At the site, a HIMA HIMax unit will act as a combined Data Concentrator and large Programmable Logic Controller (PLC), communicating with around 100 network boxes distributed over three fibre optic control loops.

Each network box will then interface with up to 12 Remote I/O boxes, which in turn will have 25 channels for physically interfacing with motorised valves, switches, sensors and other hardware.

The HIMax unit at the heart of the new PLC network is a Programmable Electronic System (PES) – HIMA’s flexible platform for large, critical production processes. In its role at the refinery, the HIMax will be the focal data point for the site’s Honeywell EPKS Distributed Control System (DCS). The HIMax will be processing an anticipated 20,000 channels of data, with scope for expansion, and delivering a complete loop response time of less than one second – from field initiation to DCS transmission.

Also key to this comprehensive upgrade programme is the requirement to use off the shelf hardware around the site and open standard communication media protocols (namely Ethernet and Modbus).

The installation work is being done ‘live’ in that small local areas are shut down for a few hours at a time while the remote I/O and network boxes are migrated to take the place of legacy, stand alone PLCs. This is possible thanks to HIMax providing uninterrupted system operation while still accommodating changes, additions, maintenance and proof tests. This negates the need for a site wide shutdown, thus minimising down-time.

Eddy Turnock, Hima-Sella’s sales and marketing director, commented, “We’re delighted to have received acceptance of our Remote I/O and Network box designs, as this enables us to commence work on the upgrade and enter volume production on several hundred units.”

In addition, under the site wide PLC upgrade contract, Hima-Sella is project managing the complete supply chain. Turnock concluded, “We have a very good working relationship with the refinery and they chose Hima-Sella because they are familiar with not only the HIMA equipment but also Hima-Sella’s track record of project management.”