In the first of a two part feature, Toni Ott of Cooper Crouse-Hinds explains how important it is that engineers fully understand the implications of modifying enclosures to house electrical apparatus for use in explosive atmospheres

In the first of a two part feature, Toni Ott of Cooper Crouse-Hinds explains how important it is that engineers fully understand the implications of modifying enclosures to house electrical apparatus for use in explosive atmospheres

For end users and installers, it is vital that the implications of modifying enclosures are fully understood, whether it be sourcing Ex d flame-proof equipment for offshore oil platforms or onshore petrochemicals plants. It is important that end users fully appreciate what they are allowed to do with that Ex d enclosure so as not to invalidate the certification of the complete equipment.

The primary function of an Ex d enclosure is to prevent the propagation of an internal explosion to the surrounding explosive atmosphere, and protecting the internal components from the environment, humidity, dirt, dust or water. With Ex d flame-proof enclosures, it is critical that the flamepath is not damaged. The external enclosure of any flameproof electrical equipment is designed to withstand an internal explosion. The enclosure joints therefore permit and control the resulting expansion of flames and hot gases – as these are relieved through the joints, preventing that explosion transmitting through to the external atmosphere. The relevant European (EN 60079-1) and international standards (IEC 60079-1) in addition to EN/IEC 60079-0 ‘General Requirements’ apply.

In Europe, manufacturers and end users have to consult two directives – 94/9/EC covers equipment and protective systems intended for use in potentially explosive atmospheres (ATEX) and is for the manufacturers of the equipment. For end users, Directive 1999/92/EC ‘Risks from Explosive Atmospheres’ (December 1999) outlines and harmonises the minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres. There is no directive covering the middle ground i.e. modifying an existing Ex d enclosure by neither a manufacturer nor within the full responsibility of the employer (end user). Once Ex d equipment has left the manufacturer and its quality system (requirement to affix the CE mark on the type label), it is no longer the responsibility of the manufacturer but lies with the end user.

Common pitfalls

Common pitfalls

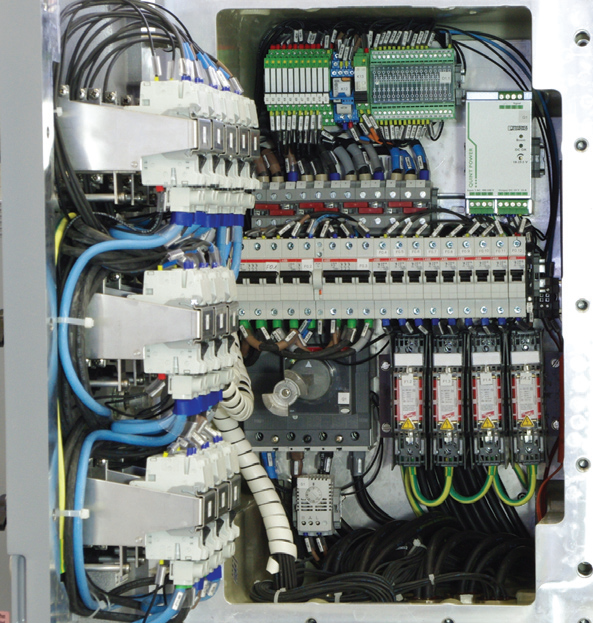

It is vital to increase awareness of relevant standards and education, as a lack of knowledge or inexperience can lead to mistakes. One of the most common mistakes made by end users and installers is to drill new cable gland entries into an Ex d enclosure after or prior to installation. If space allows, an end user may decide to fit additional components into the enclosure such as a switch or an additional component with relevant power loss.

This type of modification can affect the temperature class rating of the equipment’s enclosure or could lead to the overheating of other components inside the box, which in turn, may result in component failure or give rise to an ignition source.

In addition, these modifications could also weaken the mechanical integrity of the enclosure or lead to altered flame propagation, resulting in excess of the maximum permitted reference pressures. Also, the results of the flame transmission test performed during the EC type examination procedure could be negatively affected and a possible internal ignition will not be safely controlled by the existing flame-proof enclosure from the external explosive atmosphere. Therefore, according to Directive 94/9/EC, only the manufacturer shall carry out such modifications. If the modification is carried out by another party, without control of the quality management of the original manufacturer, the marking on the equipment is no longer valid.

Therefore, if any modifications are made to an Ex d enclosure and these are not within the responsibility and agreement of the equipment manufacturer, only two options exist:

l 1. New EC type examination certificate with new type label is the responsibility of the legal entity modifying the equipment.

l 2. The end user takes full responsibility which means they also become responsible for any subsequent failures of the enclosure that could lead to serious health and safety risks.

Other examples

Other examples

Other examples of modifying an Ex d enclosure include accidentally damaging the flame-proof gap. When opening heavy enclosures, which typically involves unscrewing fasteners and lifting the cover, maintenance technicians must be careful not to inadvertently scratch or damage the flanges or threads. The cover should be lifted slowly and smoothly off the enclosure.

Another common mistake when placing the cover back on an Ex d enclosure is to fasten the screws to the wrong torque or to forget to replace screws. This is particularly important on Ex d gas group IIC enclosures (including IIB + H2), where the tolerance of the flame-proof gap is typically down to 0.1mm. It is critical that all screws are tightened to the correct torque as specified by the manufacturer. If this isn’t done, the cover can bend and lead to an uneven flame gap. Of course, the same problem remains for IIB and IIA enclosures.

With flame gaps, the impact of grease is also important. Often, there are misunderstandings amongst end users and installers about which greases should be used with an Ex d enclosure. In general, the grease that should be used is the one recommended by the manufacturer. The message is clear for all cases – if you are in doubt, consult the enclosure manufacturer for advice and guidance on grease selection. The grease recommended by the manufacturer will have been tested at the applicable ambient temperature range. Incorrectly selected grease may harden at low temperatures or may turn into an adhesive at higher ambient temperatures.

Part two of this feature will appear in the May issue and will cover the relevant standards to consult and certification tests.

Cooper Crouse-Hinds

T: 0247 630 89 30