The IP rating is one of the most critical factors when considering which electrical enclosure or junction box should be used to protect electrical systems. As such, Chris Lloyd, general manager for Spelsberg UK, explains how different IP ratings can be reached and how to maximise your enclosure’s integrity

The IP rating is one of the most critical factors when considering which electrical enclosure or junction box should be used to protect electrical systems. As such, Chris Lloyd, general manager for Spelsberg UK, explains how different IP ratings can be reached and how to maximise your enclosure’s integrity

IP ratings relate to the degree of protection that a housing offers against ingress from foreign bodies and moisture. The rating system utilises the letters IP (ingress protection) followed by two digits – the first to indicate protection against foreign bodies and the second to indicate protection from moisture. As the numbers get higher so too does the level of protection – IP68 being the highest.

Delivering such protection is the result of many years of research and development from manufacturers. Two enclosures which offer the same level of overall protection may achieve it in very different ways – which can impact on the purchase cost, installation time and longevity of the product. Understanding the different techniques is vital in choosing the correct enclosure.

Ingress

Ingress

Debris or moisture can enter the enclosure through gaps between the body of the product and its lid. No matter how precisely an enclosure is manufactured, particles of dust and water droplets will be able to fit through the gaps which are left if a seal is not employed. This is why high quality enclosures will often feature sealing arrangements to ensure absolute protection.

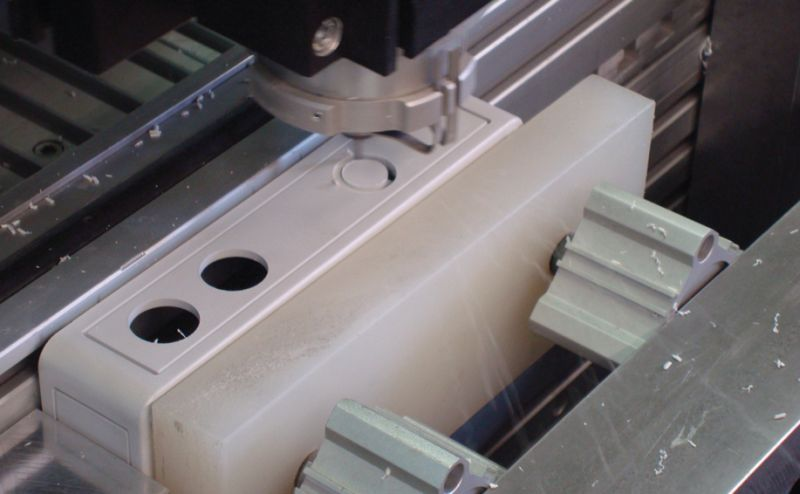

To guarantee that its seals won’t fail, Spelsberg has invested in developing an injection moulding technique which means the seal is formed as a single construction which is an integrated part of the enclosure.

Enclosures which are designed to offer higher IP ratings will typically require tooling to fix the lid in place. This plays an important part in making sure that the seals are securely pressed flush against the surface, and that small impacts won’t affect this. Medium and low IP ratings are more often supported with a ‘push-click’ mechanism which is quicker to use but allows for a small degree of movement once closed. Hinges and other accessories may also affect the enclosure’s IP levels – while they may offer improved access for the user they also generate more gaps through which foreign bodies or moisture could infiltrate.

Silicone gel

Silicone gel

A popular technique which is used to deliver an IP rating of IP68, is to fill the enclosure with a silicone gel after the connections have been made, thus completely isolating the electrics from the external atmosphere.

Using gel to protect the contents of an enclosure means that an IP68 rating is easier to achieve and doesn’t require such expensive tooling. This means that the units are often supplied cheaper. Because of the guaranteed internal protection there is also little need for screw down lids. This can speed up the installation process and ultimately improve the profitability of jobs which involve numerous installations.

However, there is a down side to silicone gel as it is impossible to access the connections without breaking the gel apart once it has been set. This means that, in applications where regular updates or routine maintenance may be required, they can prove time consuming and expensive as a new gel pack will be required each time.

Entries

A final consideration when specifying the enclosure is the number of entries that may be required and ways in which the entry option is presented. As standard many enclosures are available with knock-out points around the walls of the unit which can be removed using the correct tools. This method is preferable to pre-cut holes as it means that the enclosure is supplied with its IP rating intact. However, there is a fine balance between the knock-outs being extremely hard to remove and being too easy – either vastly increasing installation time or risking accidental removal once in the application.

Specifying the correct enclosure is only the first step in delivering a housing solution which meets the correct requirements. As soon as a cable enters the unit its IP rating is compromised, which means that specifying the correct entry sealing solution is equally important. For high IP ratings the traditional dome topped cable gland offers absolute security while ‘push-fit’ membranes offer a speedy solution for applications which are less exposed to the elements.

Finally it is important to check that the installation process does not risk compromising the effectiveness of the enclosure’s designed-in protection. Often a customer will have specified a high rating enclosure with dome topped cable glands and after a few months found that there has been water or dust ingress. Below are some classic mistakes to avoid:

• Positioning the entry points on the top side of an enclosure located outside, where puddles of water are likely to collect around the seal and be drawn in by heat expansion and contraction.

• Fixing caution notes and signs to the lid of an enclosure with screws that perforate the enclosure.

• Not fitting breather valves in high humidity environments with a large temperature differential.

• Compromising the enclosure by fixing it to a wall or bulkhead through the back panel.

• Using enclosures with loose gaskets that fall out of place as the lid is closed or tightened up.

Mistakes like this are easy to avoid and any good supplier should be able to offer advice. It’s always worth asking how an enclosure’s IP rating is achieved – most suppliers should be able to show you the different options available and help you in the specification process.

Spelsberg

T: 01952 200 716