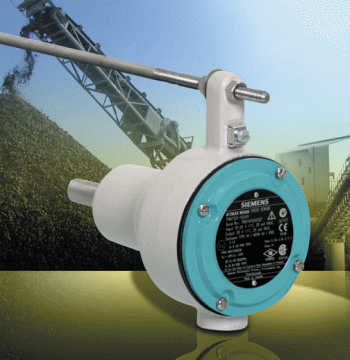

Siemens Industry Automation Division has introduced its new Sitrans WS300 shaft driven speed sensor aimed at providing consistent and accurate results in industrial applications. The sensor can be combined with a Milltronics BW100 or BW500 integrator or Siwarex FTC PLC module, as well as the Milltronics belt scale.

Siemens Industry Automation Division has introduced its new Sitrans WS300 shaft driven speed sensor aimed at providing consistent and accurate results in industrial applications. The sensor can be combined with a Milltronics BW100 or BW500 integrator or Siwarex FTC PLC module, as well as the Milltronics belt scale.

Resolutions of 22, 32, 256, 1,000 and 2,000 pulses per revolution enable the new sensor to monitor low to high speed applications. Its low weight (1.22kg/2.68lbs), helps prolong bearing life, thus reducing the overall cost of ownership.

The WS300 is also suitable for heavy industries as well as for outdoor installations, thanks to a rugged, cast aluminum housing, and is also available in stainless steel for harsh and food processing applications. The WS300 also has hazardous dust approvals, IP65 and NEMA 4X.

The Sitrans WS300 can be directly coupled to a rotating tail or bend pulley shaft, helping to ensure accurate belt travel read-out, eliminating problems caused by belt slippage or material build-up. The new sensor monitors belt speed and can be used as an input to an integrator, which calculates flow rate, totalised weight, belt loading and belt speed. It can also be combined with a Milltronics BW100 or BW500 integrator or Siwarex FTC PLC module, and a Milltronics belt scale for a complete weighing system.