At the Sensors & Instrumentation exhibition (30th September – 1st October 2014) at the NEC, Birmingham, Micro-Hybrid Electronic (stand A1), a high-tech manufacturer of micro-systems technology and infrared components and part of the Micro-Epsilon Group, will use the show to officially launch its products into the UK market. Micro-Epsilon and Micro-Hybrid (stand B38/A1) will share a stand at the exhibition.

At the Sensors & Instrumentation exhibition (30th September – 1st October 2014) at the NEC, Birmingham, Micro-Hybrid Electronic (stand A1), a high-tech manufacturer of micro-systems technology and infrared components and part of the Micro-Epsilon Group, will use the show to officially launch its products into the UK market. Micro-Epsilon and Micro-Hybrid (stand B38/A1) will share a stand at the exhibition.

Micro-Hybrid develops mechanical microelectronics and infrared systems. Working in the development of customer-specific infrared sensors, Micro-Hybrid is the only company worldwide that offers a complete product portfolio for NDIR gas- and liquid- analysis. A team of physicists, technologists and engineers designs hybrid solutions and LTCC technology for global core markets, including medical and environmental technology, industrial and aviation.

Micro-Hybrid was established in 1992 in Hermsdorf, Thuringia, a region in Germany known for its tradition in ceramics. Among the company’s core competencies are industrial ceramics (hybrids), which are invaluable for customer-specific applications such as harsh environments or high temperatures. As a result, Micro-Hybrid offers a wide range of components for electronics applications including sensors and industrial systems for regulation, control and measurement. The company’s micro systems are used in eddy current sensors for non-contact distance measurement and in flow sensors to determine the flow rate of oily or aqueous media. Infrared components are used for non-contact temperature measurement, flame detection, gas measurement and analysis of liquids.

Micro-Epsilon will present its full range of sensor technologies at the show, including non-contact eddy current and laser displacement sensors, infrared temperature sensors, thermal imaging cameras, draw wire sensors, and colour recognition sensors. It’s been a busy year for Micro-Epsilon in terms of new product developments. Highlights on the stand will include four recently launched products:

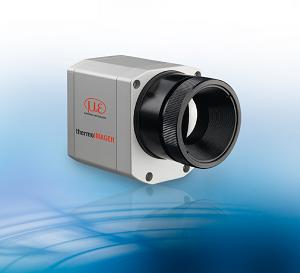

The smallest VGA-resolution infrared camera available today, the thermoIMAGER TIM 640 has dimensions of 45x56x90mm and weighs just 320g. Compared to other similar-size cameras, the TIM 640 is the only camera that enables the recording of radiometric video images at 32Hz and a VGA resolution of 640×480 pixels. The camera can detect very small temperature differences (thermal sensitivity: 75mK) and can measure object temperatures from -20°C to +900°C. For easy process integration, the camera’s TIM Connect software enables users to document measurements and to edit infrared video images. The software provides quick and easy set up together with a range of tools that enable the cameras to be used in R&D tasks as well as process control.

The scanCONTROL 2600 / 2900 COMPACT series of lightweight 2D/3D laser profile sensors are small enough to fit into a suit jacket pocket. The sensors offer a range of technical advantages, flexible installation options and versatile interfaces. The controller and electronics are integrated directly in the sensor, making them suitable for high precision profile and dimensional measurements in automation, systems integration, machine building, robotics, automotive production and other applications where space is restricted or where low sensor weight is critical.

For measurement tasks that require maximum precision (e.g. electronics R&D and production, semiconductor manufacturing) the IFS 2405 confocal chromatic sensor offers extremely high sensitivity and sub-micrometre resolution, providing advantages when it comes to inspecting the shape and size of small structures (e.g. MEMS) during or post-production. These sensors can be integrated to linear X-Y stages, machine tools or special purpose inspection systems. As well as distance measurements on reflective and transparent materials, the sensors can also perform one-sided thickness measurement of clear film, PCBs or layers.

The capaNCDT 6200 is a highly precise, integrated measuring system that includes a control unit, demodulator and Ethernet interface that supports fast and easy configuration through a web browser. The system allows up to four additional measurement channels to be added (or removed) to the base controller unit without any loss of performance or disruption. Any Micro-Epsilon capacitive displacement sensor can be connected to the controller without any additional calibration required. As a multi-channel device with nanometer accuracy (resolution is down to 0.002µm), the capaNCDT 6200 can be used in a variety of non-contact displacement, position and distance measurement applications. Measuring ranges are from 0.05mm to 10mm.