In its small component metering in the explosive area, Henkel is using BARTEC’s remote I/O system ANTARES for the first time in its dispersion and solvent adhesives operation in Düsseldorf.

In its small component metering in the explosive area, Henkel is using BARTEC’s remote I/O system ANTARES for the first time in its dispersion and solvent adhesives operation in Düsseldorf.

Henkel became a manufacturer of adhesives somewhat unintentionally when, in 1923, a shortage of packaging adhesives threatened to hinder the labelling of products. Today, the global player is a world market leader in a number of sectors, including adhesives, sealants and surface technology. One of the recipes for success is the use of tried and tested standards. By using the remote I/O system ANTARES from BARTEC in its small component metering, the tech team deviated from its previous line. The high flexibility, simple handling and above all the missing galvanic isolation as a result of the Ex e connection area on the head module forced the technicians to think differently. Another convincing argument was the fact that the system could be easily expanded both in the explosive area and outside it.

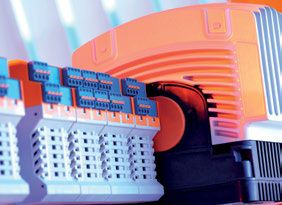

Robert Ciupka is responsible for the complete EMC planning, scheduling and maintenance along with another colleague in the operation at Henkel. The tech team do a lot of the construction and scheduling themselves in the dispersion and solvent adhesives operation in Düsseldorf. Around 120 staff are responsible for the smooth manufacture of the largely water-based adhesives H containing solvents for wall and floor covers for professional tradesmen. The facility has a high-bay store installed for a total of 12 containers. The system in the explosive area, which meters the raw materials via a weighing container and output distributor into the eight large stirring units, is controlled by BARTEC’s remote I/O solution ANTARES, designed for the explosive area. All the components, from the light cabinets to the initiator responses, analogue values of the positioners and pressure measurements, pulse counters for flow measurements, pumps or overflow prevention devices, can be directly connected through the system and coupled to the process control system via PROFIBUS.

Robert Ciupka is responsible for the complete EMC planning, scheduling and maintenance along with another colleague in the operation at Henkel. The tech team do a lot of the construction and scheduling themselves in the dispersion and solvent adhesives operation in Düsseldorf. Around 120 staff are responsible for the smooth manufacture of the largely water-based adhesives H containing solvents for wall and floor covers for professional tradesmen. The facility has a high-bay store installed for a total of 12 containers. The system in the explosive area, which meters the raw materials via a weighing container and output distributor into the eight large stirring units, is controlled by BARTEC’s remote I/O solution ANTARES, designed for the explosive area. All the components, from the light cabinets to the initiator responses, analogue values of the positioners and pressure measurements, pulse counters for flow measurements, pumps or overflow prevention devices, can be directly connected through the system and coupled to the process control system via PROFIBUS.

Standing out from the crowd

Standing out from the crowd

Ciupka built a prototype system in his office which could be easily parameterized. The first tests already showed that ANTARES is extremely flexible. “The configuration can be changed very quickly, meaning that goals can be achieved in a short time. The software ANTARES Designer provides a graphical representation of which components need to be asse mbled and it is impossible to make any major mistakes anywhere,” reports the engineer. After this, the data are loaded into the head-end. If there has been a misconnection, an error message appears immediately and also shows where the error has occurred.

mbled and it is impossible to make any major mistakes anywhere,” reports the engineer. After this, the data are loaded into the head-end. If there has been a misconnection, an error message appears immediately and also shows where the error has occurred.

Thanks to its flexible system approval, ANTARES has fulfilled the most important criterion for Ciupka and his team: “We have to remain highly flexible at all times. Today we are building systems in one way and tomorrow in another.” It emerged, for example, in the middle of a small component metering project that a few more pumps and a tank emptying  system were required and that the concept and scheduling had to be altered. In other systems, this means that the customer has to cancel the order and re-order everything if not enough reserve I/Os had been planned for in advance, as the approval is rigidly coupled to the complete system consisting of the housing, isolating assemblies and remote I/O.

system were required and that the concept and scheduling had to be altered. In other systems, this means that the customer has to cancel the order and re-order everything if not enough reserve I/Os had been planned for in advance, as the approval is rigidly coupled to the complete system consisting of the housing, isolating assemblies and remote I/O.

Quicker to the goal

THE TECHNOLOGY IN DETAIL

Experience ANTARES, the new bus technology, online:

|

If a certain number of I/Os is planned for, it is not long until the limits of conventional systems are reached if further expansion is desired. This means that an additional head-end must be procured. “There are always problems, because I have to retain the galvanic isolation,” say Ciupka of the limitations. “That was a decisive point for me, as here in the facility we always have to keep expanding and converting.” With ANTARES from BARTEC, this is different. Here, each ANTARES has its own approval and an additional flexible system approval.

If the systems have to be expanded at any point that is not directly connected to the housing, or if the housing has become too small, the user can install a transition module and link the next switching cabinet from up to 20 m. If the reserve is exhausted, the user can simply expand his system with a few extra cards.

“At any time, we can add interface assemblies in another housing at a certain distance without having to isolate the PROFIBUS separately again,” explains Ciupka, who adds: “If I need to expand the system, I can do this directly on the remote I/O, as it is the last unit on the PROFIBUS strand. Using the PROFIBUS cable, I can move out of the explosive area and install the second slave where I need it. That is a huge advantage for me.”

The fact that the system can work without isolators does not just reduce costs, it also increases the availability of the systems at Henkel. With ANTARES, the user can work in an explosive area immediately; an aspect which should not be underestimated.